Comprehensive Guide to Air Compressor Selection for Penicillin Production Enterprises

1. Stringent Requirements for Air Compressors in Penicillin Production

Penicillin production is a highly sensitive biological fermentation process with requirements far exceeding ordinary industrial standards, focusing on:

- Sterile and Pure Air Source: Microorganisms in fermentation are extremely sensitive to air quality. Even trace oil contamination (>0.01mg/m³) or microbial contamination can cause bacterial death and process failure.

- Stable and Reliable Operation: Continuous production demands air compressors with high reliability. Unexpected downtime can lead to significant economic losses.

- Compliance with Strict Standards: Must meet GMP regulations, ISO 8573-1 Class 0 oil-free standards, and international certifications like FDA and EU GMP.

2. Core Elements of Air Compressor Technology Selection

(1) Types and Application Scenarios of Oil-free Compression Technology

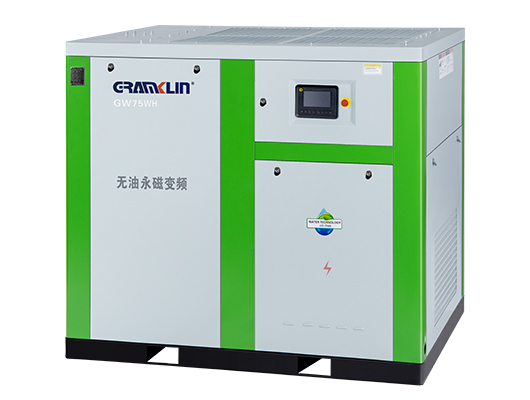

- Oil-free Screw Air Compressors: Use synchronous gear-driven twin-screw rotors for contactless compression. Ideal for medium-to-large enterprises with high air volume requirements.

- Oil-free Scroll Air Compressors: Feature precision motion between fixed and moving scrolls, offering simplicity and low noise suitable for small-to-medium workshops.

- Oil-free Piston Air Compressors: Excel in small air volume scenarios but require self-lubricating piston rings for extended service life.

(2) Key Component Design Considerations

- Material Selection: 316L stainless steel for compression chambers and pipelines to prevent corrosion.

- Sealing Technology: Full-metal bellows or fluororubber seals for corrosive environments.

- Bearing Configuration: Ceramic or air bearings eliminate contamination risks from traditional grease lubrication.

3. Effective Approaches to Energy Consumption Optimization

(1) Advanced Variable Frequency Drive Technology

Vector frequency conversion technology enables automatic speed adjustment based on air demand, reducing energy consumption by over 30%.优先选用 IE4 及以上能效等级的电机,以进一步提高能源利用效率。

(2) Waste Heat Recovery System

Recover waste heat from compressors to generate hot water/steam for cleaning or process heating, lowering overall energy costs.

(3) Intelligent Control System

Networked multi-compressor control optimizes operating units according to real-time demand, preventing inefficient “oversized” operation.

4. Key Environmental Protection Measures

(1) Environmental Benefits of Oil-free Processes

Eliminate waste oil generation and associated environmental risks inherent in traditional oil-lubricated systems.

(2) Low-emission Refrigeration Solutions

Use eco-friendly refrigerants like R134a and optimize cooling systems to reduce carbon footprint.

(3) Noise Control Measures

Employ soundproof enclosures and vibration-damping mounts to maintain noise levels below 85dB in cleanrooms.

5. System Configuration Optimization Recommendations

(1) Multi-stage Filtration System

Three-stage filtration (5μm pre-filter, 0.01μm precision filter, 0.22μm bacterial filter) ensures air purity.

(2) Deep Drying System

Combination of refrigerated dryers (-20℃ dew point) and adsorption dryers (-70℃ dew point) or membrane dryers for varying requirements.

(3) Online Monitoring System

Real-time monitoring with dew point meters, oil content detectors, and microbial counters ensures continuous compliance.

6. Installation and Maintenance Considerations

(1) Installation Environment Requirements

Install in dry, ventilated rooms away from dust/corrosive gases with proper drainage systems.

(2) Maintenance Schedule Recommendations

- Replace air/precision filters every 2000 hours.

- Inspect/replace seals annually.

- Perform comprehensive maintenance (bearings/rotor alignment) every 3 years.

(3) Compliance Verification Requirements

Regular third-party testing to confirm ISO 8573-1 Class 0 compliance and maintain records for audits.

7. Typical Case Analysis

- Equipment Selection: Two oil-free screw compressors (15m³/min each) with waste heat recovery.

- System Configuration: Three-stage filtration + refrigerated-adsorption drying (-40℃ dew point).

- Intelligent Control: Cluster control system adjusts operation based on real-time demand.

- Results: 28% energy savings, 99.7% fermentation success rate, 40% maintenance cost reduction.

8. Conclusion and Outlook

Air compressor selection for penicillin production is a multi-faceted engineering task requiring consideration of technical, economic, and environmental factors. Choosing Class 0-certified oil-free compressors with optimized configurations and intelligent controls ensures efficient, stable, and sustainable operations. Future trends will focus on further energy savings, smart integration, and eco-friendly designs to provide better air quality assurance.